Non-Destructive Testing (NDT) Excellence

At Hansal, our commitment to quality extends to our Non-Destructive Testing (NDT) processes, ensuring the utmost integrity in every weld and fabrication. Here's a detailed overview of our NDT procedures, designed to meet and exceed industry standards:

1. Visual and Weld Size Inspection:

Our meticulous NDT process begins with a comprehensive visual inspection, scrutinizing every weld for visual imperfections and confirming adherence to specified size requirements. This initial step sets the foundation for the quality of our fabrication work.

2. Magnetic Particle (MT) Test:

As part of our NDT protocol, we conduct Magnetic Particle Testing with the percentage outlined in the Inspection and Test Plan (ITP). This method detects surface and near-surface flaws, ensuring that even the slightest imperfections are identified and addressed.

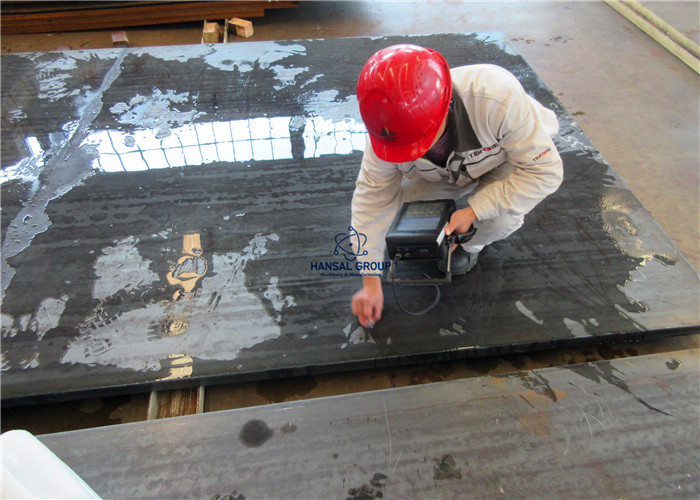

3. Ultrasonic (UT) Test:

Our Ultrasonic Testing is performed in accordance with the percentage specified in the ITP. This advanced method allows us to assess the internal structure of welds, ensuring a high level of precision in identifying potential defects and ensuring the overall structural integrity of the fabricated components.

4. Additional Tests as Required:

Beyond the standard inspections, we are prepared to conduct any additional tests necessary to meet specific project requirements. Our flexibility ensures that we adapt our NDT approach to address the unique demands of each project, guaranteeing the highest quality and safety standards.

At Hansal, our NDT procedures stand as a testament to our unwavering commitment to excellence in steel fabrication. Trust us for thorough inspections that go beyond industry norms, ensuring the structural soundness and durability of every component we deliver.

Hansal

Hansal